Inspection Facility

Inspection Facility

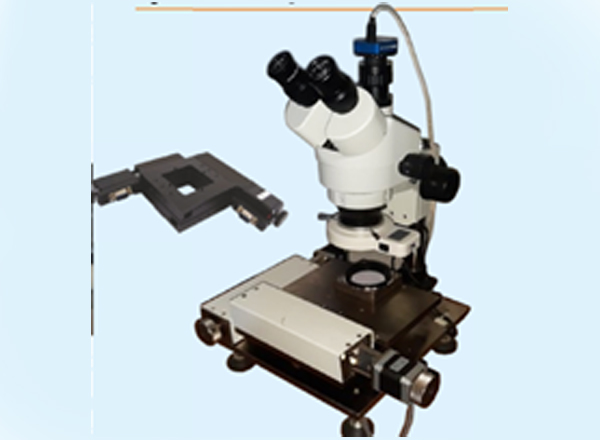

Our inspection facility is equipped with advanced microscopes for precise visual examination and measurement of metal tubes and hose assemblies. This ensures accurate detection of surface defects, dimensional accuracy, and material integrity. Our skilled quality team uses high-resolution imaging to verify every detail, maintaining strict quality standards and ensuring flawless products that meet customer specifications and industry requirements.

Key Features

- Equipped with high-resolution industrial microscopes

- Enables detailed visual and dimensional inspection

- Detects surface defects and imperfections accurately

- Ensures material integrity and consistency

- Supports precision measurement and documentation

- Operated by trained and skilled quality personnel

- Inspection Facility

- CNC Vision Measuring Machine

- 3D Scanning

- Particle Weight Analysis System

- Microscope for Partial Size Analyser

- Salt Spray Test Chamber

| Instument | Qty | Specification |

|---|---|---|

| VMM | 1 | L200xW200XH150 mm |

| 3D Scanning | 1 | 30 Blue laser accuracy 0.020 mm |

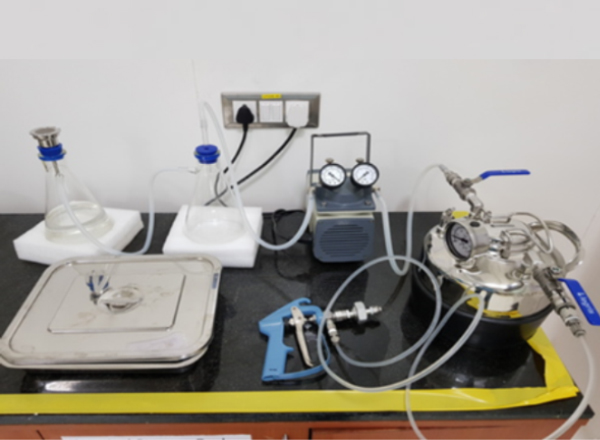

| Particle weight analysis system | 1 | Contamination Analysis kit Extra Accessories & Consumables: + Weighing Balance |

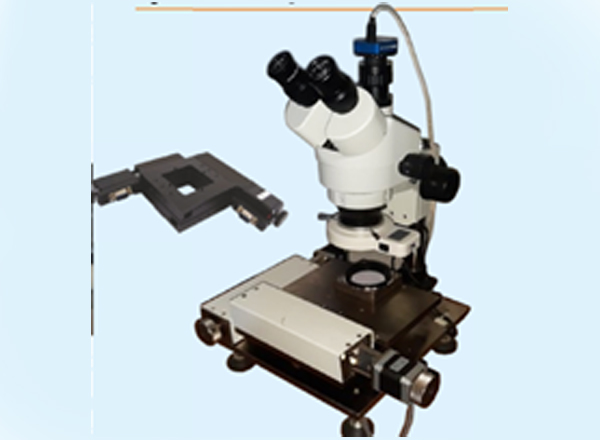

| Stereo motorized Microscope System | 1 | Millipore Particle Analysis System –XY Stereo motorized Microscope System Imported stage and high-quality resolution and fully automatic analysis + Welding Penetration System |

| Salt Spray Chamber | 1 | Salt Spray Chamber Model-DQS 270 + digital PID controller chamber capacity- 270 L |

| Digital Vernier | 1 | 0 to 150 |

| Digital Vernier | 1 | 0 to 300 |

| Digital Micromerer | 1 | 0 to 25 |

| Suraface Table | 1 | 1250x1500x300 |

Automatic High Precision 3 axis measurement System. The Machines offers you powerful 3 axis measurement solution with high accuracy & High precision. It provides you fast & accurate measurement of complex precision parts. The image processing technology & high-speed stage control enable high-through output measurements, which make the machines optimal solution for work piece that have many features to be measured. With the ATQ METRO measuring software, the machine is capable to offer powerful 2D/3D composite measuring function. the machine is able to work with touch probes & non/contact measuring sensors, which gives more possibilities and efficiency to the series.

Features

3D scanning is a technology used to capture the exact shape and dimensions of physical objects and convert them into digital 3D models. In the automotive industry, it plays a crucial role in design, quality control, reverse engineering, and production.

Applications of 3D Scanning in Automotive

A Particle Weight Analysis System is a measurement setup used to analyze, detect, and quantify particulate contamination (dust, metal chips, fibers, etc.) in components, fluids, or assemblies. It is mainly used to ensure cleanliness levels in automotive components such as hydraulic systems, fuel systems, brake lines, and engine parts.

Purpose

A microscope for particle size analysis is used to observe, measure, and classify particles collected during cleanliness or contamination analysis. It helps identify particle size, shape, and material type (metallic, non-metallic, or fibers).

Key Features

Salt Spray Test Chambers offer the most realistic and dependable corrosion test, widely used to test corrosion resistance of automotive, paint, surface coating, chemical, aerospace, electronics, car industry, offshore and defense industries

Features